CI Staves

CI staves are used for cooling the referectory linings below the throat region of Blast furnace

Please contact us for further details

Checker Plates

as a support to the hot stoves and facilitiate the air flow.

Please contact us for further details

Bell Less Top

To pour the charge and coke inside the furnace or hearth

Sinotop Metallurgical Equipment & Technology (Beijing) Co., Ltd.

Torpedo Ladle Car

torpedo ladel car is a huge ladel-car assembly where it is used to carry molten iron from BF to SMS

Please contact us for further details

Hot Metal Ladle and Ladle Car Assemblies

ladle is a vessel used to transport and carry molten steel from one process to another

Please contact us for further details

Tap Hole Clay/Mud Gun Mass

to tap the outlet where the hot metal is poured out at the bottom of the furnace or hearth

Please contact us for further details

Runner Castable/T S Castable

as a refractory lining for the path traced by the hot metal running outside the furnace

Please contact us for further details

MgO Bricks

It is used for ladle lining and other steel plant equipment application

Please contact us for further details

Other Special Castables

Applicable for ladle, tundish and other areas lining.

Please contact us for further details

Mud Gun Machines(Hydraulic)

to close the tap-hole of the blast furnace

Please contact us for further details

Tap Hole Drill

to tap out the molten iron below the furance or hearth.

Please contact us for further details

Tuyere Stock Assy

arrangement comprising of pieces which blow hot compressed air to the tuyere nozzles.

Dae Dong Engineering & Machinery Co.. L

BLOW PIPE

main equipement In the Tuyere stock Assembly which blows hot air.

Dae Dong Engineering & Machinery Co.. L

Cooling Stave

Sinotop Metallurgical Equipment & Technology (Beijing) Co., Ltd.

Expansion Joint

Sinotop Metallurgical Equipment & Technology (Beijing) Co., Ltd.

Filter Bag

Sinotop Metallurgical Equipment & Technology (Beijing) Co., Ltd.

Gear Box

Sinotop Metallurgical Equipment & Technology (Beijing) Co., Ltd.

Hot Air Supply Device / Tuyere Stock Assy

Arrangement comprising of pieces which blow hot compressed air to the tuyere nozzles.

Sinotop Metallurgical Equipment & Technology (Beijing) Co., Ltd.

Dae Dong Engineering & Machinery Co.. Ltd.

Wear Resistance Liner ( Hard Alloy )

.png)

Sinotop Metallurgical Equipment & Technology (Beijing) Co., Ltd.

Wear Resistance Liner (Ceramic)

.jpg)

Sinotop Metallurgical Equipment & Technology (Beijing) Co., Ltd.

Wheel Assembly

Sinotop Metallurgical Equipment & Technology (Beijing) Co., Ltd.

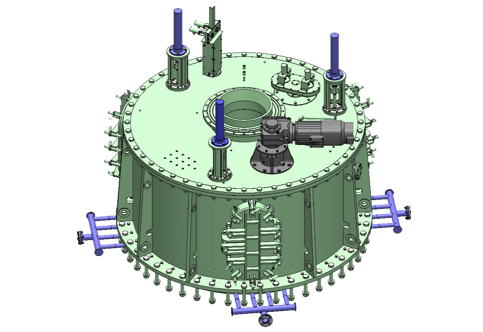

Burden Tank

Sinotop Metallurgical Equipment & Technology (Beijing) Co., Ltd.

Coned Shaped Hard Alloy Bush Matrix

Sinotop Metallurgical Equipment & Technology (Beijing) Co., Ltd.

Distribution Chute

Sinotop Metallurgical Equipment & Technology (Beijing) Co., Ltd.

Distributor

Sinotop Metallurgical Equipment & Technology (Beijing) Co., Ltd.

Expansion Joint

Sinotop Metallurgical Equipment & Technology (Beijing) Co., Ltd.

Feeder Spout

Sinotop Metallurgical Equipment & Technology (Beijing) Co., Ltd.

Feeder Spout Anti Wear Bush

Sinotop Metallurgical Equipment & Technology (Beijing) Co., Ltd.

Forged Sealing Valve Seat

Sinotop Metallurgical Equipment & Technology (Beijing) Co., Ltd.

Hard Alloy Bush

Sinotop Metallurgical Equipment & Technology (Beijing) Co., Ltd.

Hard Alloy Chute Liner

Sinotop Metallurgical Equipment & Technology (Beijing) Co., Ltd.

Material Control Gate

Sinotop Metallurgical Equipment & Technology (Beijing) Co., Ltd.

Material Receiving Hopper

Sinotop Metallurgical Equipment & Technology (Beijing) Co., Ltd.

Sealing Valve

Sinotop Metallurgical Equipment & Technology (Beijing) Co., Ltd.

Sealing Valve Actuator

Sinotop Metallurgical Equipment & Technology (Beijing) Co., Ltd.

Sealing Valve Disc

Sinotop Metallurgical Equipment & Technology (Beijing) Co., Ltd.

Upper Valve Box

Sinotop Metallurgical Equipment & Technology (Beijing) Co., Ltd.

Various Seal Rings

Sinotop Metallurgical Equipment & Technology (Beijing) Co., Ltd.

HYDRAULIC CYLINDER

HYDRAULIC OPERTED BALL VALVE (HALF BALL TYPE) INDO SAIL IISCO BLAST FUNACE DUST DISCHARGE VALVE 2009

MACHINERY TECHNOLOGY SOLUTION CO., LTD.

HEAVY DUTY PNEUMATIC BALL VALVE

POSCO GWANG YANG STEEL NO 5 SINTER PLANT PNEUMATIC BALL VALVE(250A) POSCO POHANG STEEL FINEX UNIT HIGH TEMP BALL V/V

MACHINERY TECHNOLOGY SOLUTION CO., LTD.

MOTOR OPERATED BALL VALVE

MOTOR OPERATED BALL VALVE POSCO GWANG YANG STEEL. BLAST FUNACE DUST CUTTING BALL VALVE (V-KNOTCH TYPE)

MACHINERY TECHNOLOGY SOLUTION CO., LTD.

General Tuyere Nozzle

Cu (copper) 99.7% or more Electrical conductivity 80% I.A.C.S or more ø505 x ø130 x 500mm 180 to 300 kg

Seoul Engineering Co., Ltd.

Spiral Tuyere nozzle

NOSE part: Cu (copper) 99.9% or more / Electrical conductivity 80% I.A.C.S or mo Body part: Cu (copper) 99.7% or more / Electrical conductivity 65% I.A.C.S or mo ø431 x ø130 x 505mm 180 to 350 kg

Seoul Engineering Co., Ltd.

Tuyere Cooler

Cu (copper) 99.5% or more Electrical conductivity 60% I.A.C.S or more ø750 x ø396 x 600mm 450 to 700 kg

Seoul Engineering Co., Ltd.

Cooling Plates

Cu (copper) 99.5% or more Electrical conductivity 60% I.A.C.S or more 500-1200mm x 620mm x 630mm 60 to 220 kg

Seoul Engineering Co., Ltd.

Copper Staves

Cu (copper) 99.96% or more Electrical conductivity 100% I.A.C.S or more 2,590mm x 1,210mm x 120mm about 2,000 kg

Seoul Engineering Co., Ltd.

Wheel

Sinotop Metallurgical Equipment & Technology (Beijing) Co., Ltd.

Axle

Sinotop Metallurgical Equipment & Technology (Beijing) Co., Ltd.

Planetary Gearbox

Sinotop Metallurgical Equipment & Technology (Beijing) Co., Ltd.

Brake Shoe 1

Sinotop Metallurgical Equipment & Technology (Beijing) Co., Ltd.

DCEM Brake

Sinotop Metallurgical Equipment & Technology (Beijing) Co., Ltd.

Power Connector

Sinotop Metallurgical Equipment & Technology (Beijing) Co., Ltd.

Hot wind Valve disk & Seat Ring

Cu (copper) 99.5% or more Electrical conductivity 50% I.A.C.S or more Valve disk: ø1,560 x 150mm (about 1,600 kg) Seat Ring: ø1550 x 300mm x 120mm (about 1,000kg)

Seoul Engineering Co., Ltd.

WR & IMR Chock Extractor(Single)

.jpg)

This equipment functions to automatically disassemble and assemble Roll & Chock. Its technology is necessary to the Roll Shop in the Cold Rolling Mill.

SAMWOOECO

WR & IMR Chock Extractor(Dual)

.jpg)

Facility to disassemble and assemble WR & IMR chocks on the upper and lower part simultaneously

SAMWOOECO

Bearing Washing Machine

Auto Clamp

Roll Skid

Crane

Roll Cooling System

Shot Blast Machine

Coolant System

Chock Tilter (W.R, BUR)

.jpg)

Back up Roll Chock Extractor

Conveyor/Belt Cover/Clip/Clamp

Pollution protection Equipment from scattered dust and/or rain created by installing a belt conveyor.

SAMWOOECO

Dust Scattering Prevention Cover

Equipment to block scattered dust that results from molten metal pouring. from the blast furnace and improves the dust collecting effect.

SAMWOOECO

Cover

Gas Purification Wet Scrubber

Pulverized Coal Injection Lance (moving type)

.jpg)

Slag Granulation Filter

Equipment to filter granulated slag after manufactured from the blast furnace after quick cooling.

SAMWOOECO

Slag Granulation Screw Conveyor

Equipment to transfer granulated slag after manufactured from the blast furnace after quick cooling.

SAMWOOECO

Coke Quenching Car

Equipment to cool down and transfer red-hot cokes produced in a coke oven.

SAMWOOECO

Stacker

Laddle Tilting Transfer Car

Laddle & Slag Pot Transfer Car

Slag Pot Transfer Car

RH-VTD Transfer Car

Coke Transfer Car

Top Bubbling Equipment

Improves existing L/F top bubbling equipment from reclining type to vertical type and secures stability.

SAMWOOECO

Repair Car

Brick-Building Device for a Converter

RH-VTD Vacuum Tank

F.S.B (Finishing Scale Breaker)

.jpg)

Equipment to remove scales (iron oxide) on the surface. Spray headers are installed at the top, bottom, front and back.

SAMWOOECO

Coil Lifter

Tension Leveler

Equipment to remove scales on the surface of coils by bending the cracks mechanically to release the cracks. It corrects coils so they can be made to be flat as well.

SAMWOOECO

Coil Car

Cold Rolled Bung Car

Inner Cover

Shuttle Car

Shear

Table

RCS SPRAY Nozzle

Nozzle is for cooling down the strips inside CAL furnace of cold rolling mill

SAMWOOECO

Descaler

Slag Granulation Treatment Facility

RO-RO Cassette

Mg Auto Cleaning System

A loader dedicated to the 6th Chamber of the magnesium plant. This is a system built to clean inside a retort. (Each role is divided a cooling chamber cleaner and a retort cleaner)

SAMWOOECO

Bur Removal System

Turn Over Equipment

Slab Piler Machine

W.S.U (Withdrawal Straightener Unit)

.jpg)

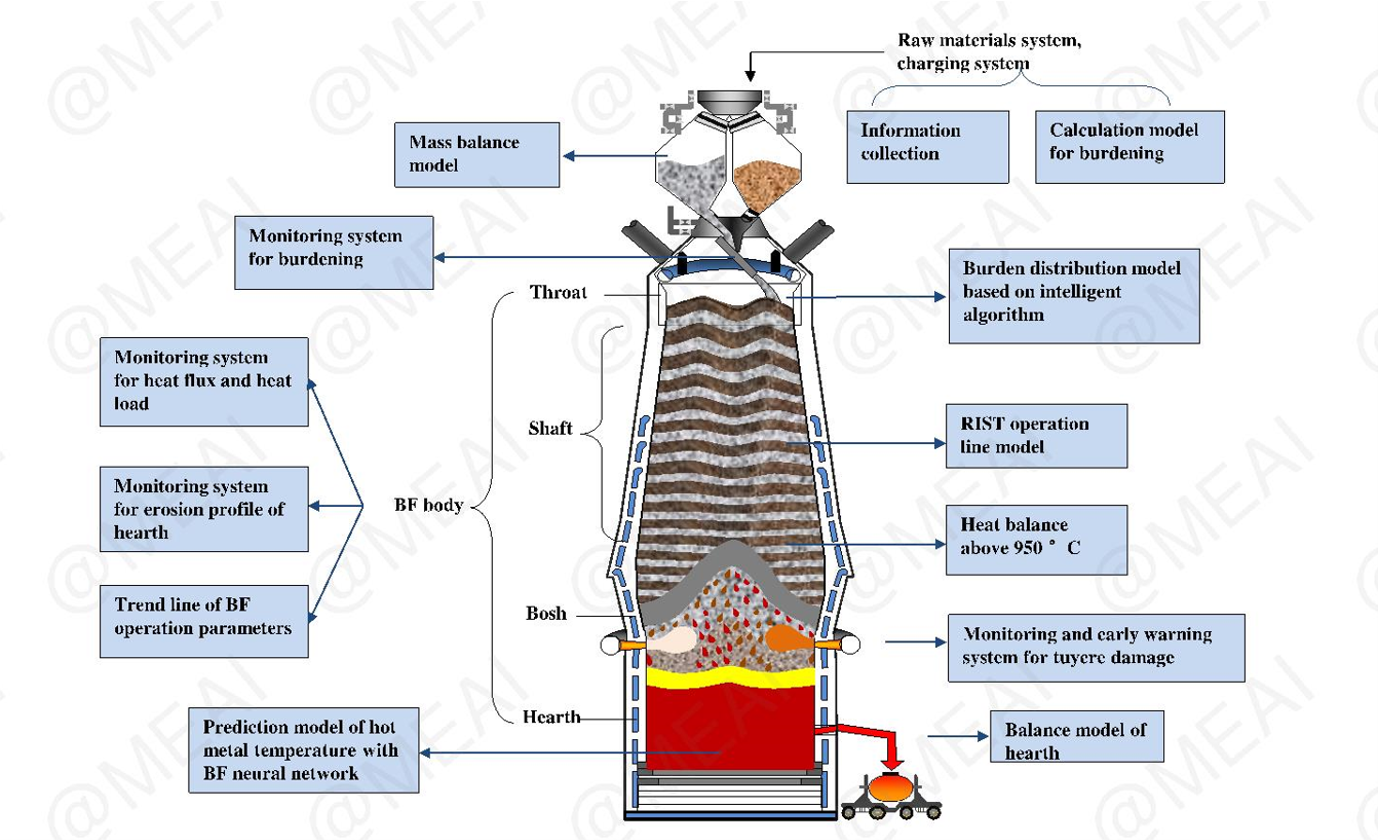

Mathematical Models of BF Process

Intelligent 3D monitoring System OF Hearth Erosion, is based on heat transfer , numerical simulation , artificial intelligence algorithm and erosion mechanism. The system can provide many functions such as 3D temperature field , dytnamic simulation image of erosion and accretion etc. And can effectively help blast furnace operator to nitice 3D erosion profile changes by detailed calculation reference.

Sinotop Metallurgical Equipment & Technology (Beijing) Co., Ltd.

Main Technical Features

Precise physical 3D modeling and automatic meshing. · The 3D temperature filed calculation model. · Calculation of 3D temperature field under dynamic erosion. · Calculation of 3D temperature field under dynamic condition. · The inverse model of 3D temperature field based on intelligent algorithm. · Erosion, protective layer location search algorithm. · 360-degress non-blind zone in three-dimensional display.

Sinotop Metallurgical Equipment & Technology (Beijing) Co., Ltd.

HD Heat Infrared Camera System

High definition burden surface and chute, clear gas flow image 1.No matter visible light or not, burden surface and part of chute HD image frame can be seen(5-10 seconds after distribution), including chute shape, lining, lining wear, operation and distribution, even stock rod position and operation. 2. Burden surface gas flow can be seen clearly inside image! Burden surface and chute online monitoring, know gas flow precisely 1. Monitor burden surface and chute temperature fully, any temperature line can be set to monitor any point temperature (multi-points monitor is available), marked point temperature can be shown. 2. No cross temperature measurement needed! Self-protection when water cooling or nitrogen cooling fails 1. PLC control, if cooling water or nitrogen, power supply fails or temperature is abnormal, camera and lens will be drawn out automatically, which can greatly improve service life of the camera. No blow down of BF is needed for equipment maintenance 1. Online equipment maintenance, without any impact on BF operation.

Sinotop Metallurgical Equipment & Technology (Beijing) Co., Ltd.